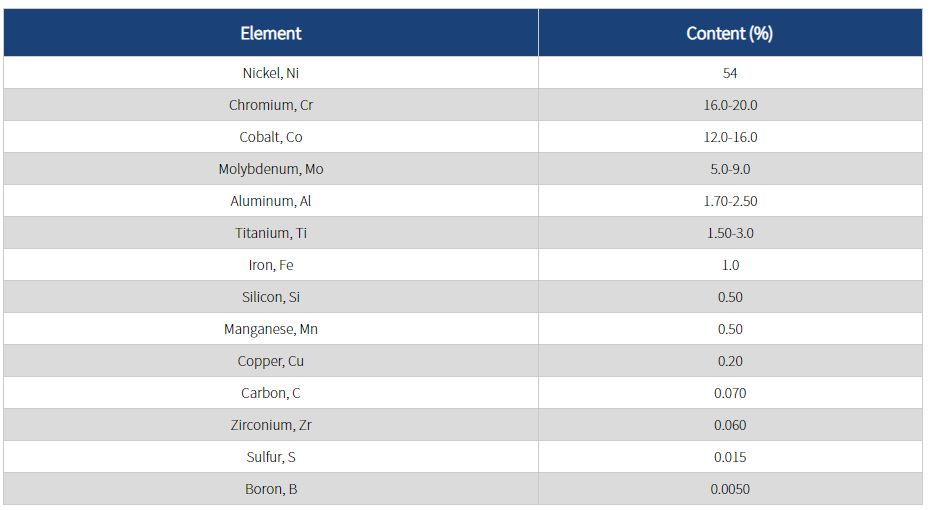

NiMONIC PK33 chemical composition:

NiMONIC PK33 is a nickel-based alloy containing iron, chromium and aluminum. The unique combination of these elements gives PK33 exceptional strength and durability. In addition, it has good resistance to oxidation and high temperature corrosion.

NIMONIC PK33 physical properties:

NiMONIC PK33 has a melting point of 1400°C (2550°F). This makes it ideal for use in extreme temperatures as it can operate safely at very high temperatures. It also has a density of 8.32 g/cc, making it a relatively lightweight material.

NIMONIC PK33 mechanical properties:

One of the main reasons NiMONIC PK33 is so popular in the aerospace and power generation industries is its excellent mechanical properties. It has a tensile strength of 1075 MPa and a yield strength of 625 MPa, making it strong and resistant to deformation. It also has good ductility, which means it can withstand high stresses without cracking.

NiMONIC PK33 uses:

NiMONIC PK33 is primarily used in the aerospace and power generation industries. Its high temperature resistance makes it ideal for use in aircraft engines, gas turbines and other high-performance applications that require materials that can withstand extreme conditions. It is also used in chemical processing plants and harsh environments where corrosion resistance is critical.

NiMONIC PK33 heat treatment:

NIMONIC PK33 can be heat treated using a variety of techniques, including solution annealing and aging. Solution annealing is the heating of an alloy to high temperatures and then rapid cooling to improve its strength and ductility. Aging involves heating the alloy to a lower temperature and holding it for a longer period of time so that the alloying elements form precipitates, further increasing its strength.

NIMONIC PK33 welding:

NiMONIC PK33 can be welded using a variety of techniques, including Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW). Welding can be challenging, however, as the alloy tends to crack due to its high chromium content. Special care must be taken when welding to reduce the risk of cracks and ensure safe and reliable welding.

NiMONIC PK33 Corrosion Resistance:

NiMONIC PK33 is known for its excellent corrosion resistance, especially at high temperatures and harsh environments. It has good resistance to oxidation, sulfidation and other forms of corrosion, making it ideal for applications where corrosion resistance is critical. However, like all alloys, PK33 can still corrode if not properly maintained.

in conclusion:

In conclusion, NIMONIC PK33 is a nickel-based alloy known for its excellent strength, high temperature and corrosion resistance. Its unique combination of elements makes it an ideal material for the aerospace, power generation industries, and other applications where extreme conditions exist. If you are using or considering using NIMONIC PK33, please consider its heat treatment, welding and corrosion resistance properties and follow best practices to ensure it performs as expected.

Tianjin Anton Metal Manufacture Co., Ltd. is a company specializing in the production of various nickel-based alloys, Hastelloy alloys and high-temperature alloy materials. The company was established in 1989 with a registered capital of 10.0 million, specializing in the production and sales of alloy materials. Anton Metal’s products are widely used in aerospace, chemical industry, electric power, automobile, nuclear energy and other fields, and can also provide customized alloy material solutions according to customer needs. If you need to know the price consultation of alloy materials or provide customized alloy material solutions, please feel free to contact the sales staff.

==========================================

www.antonmetal.com

ANTON METAL| Your specialty alloys manufacturer

Email: dominic@antonmetal.com

Phone: +8613132148618(wechat/whatsapp)

Post time: Jan-04-2024